China Non magnetic Socket Pogo Pin Probes Manufacturers|Xinfucheng

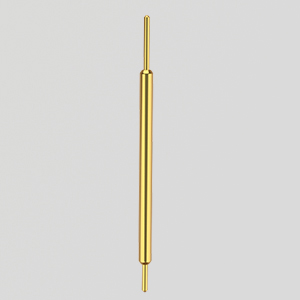

Product Introduction

What is Pogo Pin?

Pogo Pin(Spring Pin) is used to test semiconductor or PCB used in many electric appliances or electronic devices. They can be considered as nameless hero who helps people's lifestyle everyday.

We're committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for China wholesale USA Brass Short Pogo Pin, Pogo Contact, Vista HD Camera Pogo Pin, Please send us your specifications and requirements, or feel free to contact us with any questions or inquiries that you may have.

China wholesale China Pogo Pin and Connector Pogo Pin, Our company considers that selling is not only to gain profit but also popularize the culture of our company to the world. So we are working hard to give you the wholehearted service and willing to give you the most competitive price in the market.

Product Display

Product Parameters

| Part Number | Barrel Outer Diameter (mm) |

Length (mm) |

Tip for Load Board |

Tip for DUI |

Current rating (A) |

Contact resistance (mΩ) |

| DP1-038057-BB08 | 0.38 | 5.70 | B | B | 2 | <100 |

| Non magnetic Socket Pogo Pin Probes is a customized product with very little stock. Please communicate in advance before your procurement. | ||||||

Product Application

We have spring probes, which are composed of nonmagnetic material to use for test environment that requires to remove the effect of magnetism.

Maintenance of ICT test needle

The ICT test pin plays a very important role in the ICT test process. Although the probe is a consumable, but the maintenance is good, the increase of the probe life has a certain effect on the cost control. How to maintain the test needle to make it last longer, here are the five main points of probe maintenance:

1. Test environment The test environment is the main reason that the probe is contaminated with debris. For example, the test environment has more flux, or there is more dust in the air. Contamination on the probe needle will cause probe contact problems, so high standards The dust-free workshop is one of the prerequisites to guarantee the life of the probe.

2. Dust jacket Many jig factories provide dust jackets to prevent dirt from falling on the test needles and needle tubes. Especially vacant or unused fixtures. In a vacuum fixture, dust will settle around the test board and will be directly drawn into the test needle when using the vacuum instrument.

3. Process control When testing PCBs with more rosin, the probe will be contaminated with a lot of rosin. It is very important to control the amount of rosin.

4. Wiping The use of anti-static brushes is a safer and faster method. Metal brushes or hard-bristle brushes may damage the needle or the coating, which will adversely affect the test results.

5. The needle of the needle probe is easily contaminated by flux or rosin. It is recommended to clean it with a soft brush. First pull out the test probe from the jig and tie it together. Then only soak the needle part in the cleaning agent for about five Divide the seeds, wipe them with a soft brush, remove the residue and dry them, and continue the test after installation.

Keeping the test pin clean is a more effective way to reduce the test failure rate.