Company Profile

Founded in 2003, Xinfucheng Electronics Co., Ltd. is located in Shenzhen, considering high-tech electronics industry is booming. It is a professional probe and test socket manufacturer. The whole factory covers an area of 2,000 square meters. An assembly line, CNC lathe, electroplating assembly line, and complete functional testing equipment. We have the capability and solutions for complex technical problems, diversified orders, quickturn shipments, stable quality. Customized and manufactured more than tens of thousands of products for customer needs and requirements. Xinfucheng continues to introduce probe manufacturing technologies and diversification . The probe products developed through continuous research and development , breakthroughs, focusing with widely used for testing of high-tech products such as the semiconductor industry, electronics industry, and PCB industry. Quality is comparable to that of Europe,U.S., Japan and other countries have received unanimous affirmation and trust from the probe industry and endusers.

Development Path

On August 3, 2003, Shenzhen Xinfucheng Electronics Exhibition and Sales Department was formally established. At the beginning of the establishment, the main sales and distribution of test probes was based in Korea, Japan, Germany, and the United States.

The sales department of Xinfucheng Electronics started to sell probes/test scokets in large quantities to South China and East China, and the company's output value exceeded 5 million yuan for the first time.

Xinfucheng Electronics Exhibition and Sales Department established an assembly line and began to purchase foreign probe parts in large quantities for assembly and OEM sales.

In 2016, the design and manufacture of the test sockets began. It has CNC production line, heat treatment department, electroplating production line, assembly line...& to introduce excellent performance management mode.

In 2017, Xinfucheng Company put forward four major policies. Xinfucheng Company formulated the "2017~2019 Development Plan".

Business Scope

◎ Semiconductor package test pin (BGA Testing Probes)

◎ Semiconductor test socket (BGA Testing Socket)

◎ P C B Printed circuit board testing (Tradition Probes)

◎ Inline Circuit Testing.and Function (Testing Probes)

◎ Coaxial high frequency needle (Coaxial Probes)

◎ High current coaxial needle (High Current Testing Probes)

◎ Battery&Antenna Pin

Service Industry

PCB

CPU

RAM

Graphics Card

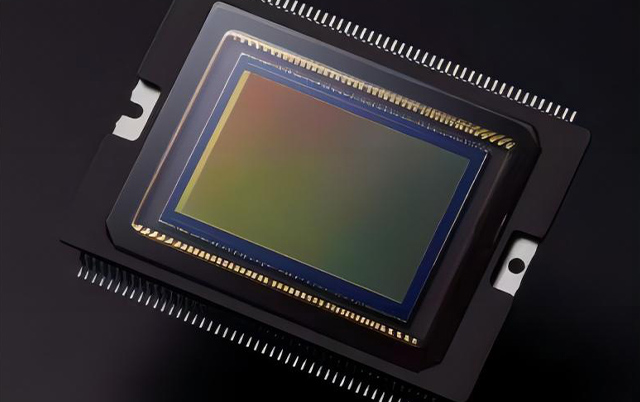

CMOS

I.C.T (Online Testing)

Test Socket Assemblies

Cameras

Mobile

SMART WEAR

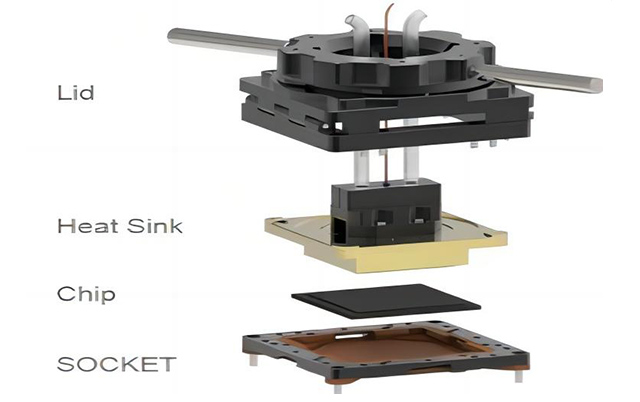

IC Methodology

Integrated circuit testing mainly includes design verification in chip design, wafer inspection in wafer manufacturing, and finished product testing after packaging. Regardless of the stage, to test the various functional indicators of the chip, two steps must be completed. One is to connect the pins of the chip with the functional module of the tester, and the other is to apply input signals to the chip through the tester, and check the chip's performance. Output signals to judge the effectiveness of chip functions and performance indicators.,

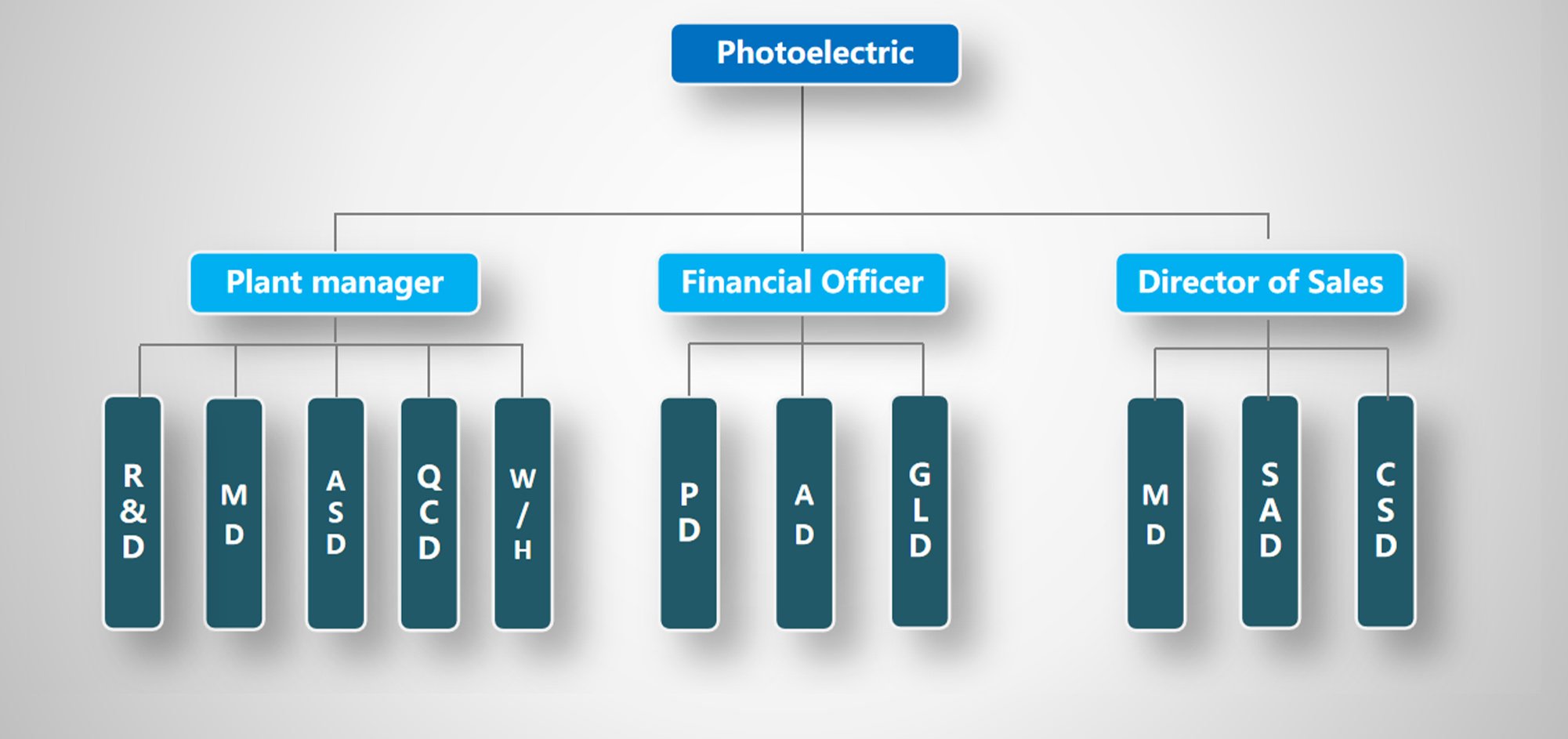

Organizational Structure